Rubber Shoe Sole Injection Molding Machine

| Categories | Rubber sole injection molding machine |

|---|---|

| Brand | professinal for rubber shoe sole injection machine |

| Model | LRS165 |

| Condition | New |

| Place of Origin | Zhejiang, China (Mainland) |

| Oil tank capacity | 600 L |

| Max Injection Volume | 1000 CC |

| Heating Plate Dimension | 400×285 mm |

| System pressure | 21 Mpa |

| Power | 90 kw |

| Dimension (L×W×H) | 3550×2020×(3200-3450) mm |

| Weight | 10.5 Ton |

| Engineers | Portugal team |

| FOB port | Ningbo port, Shanghai port |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Apr 25,2025 |

Detail Information

precision rubber sole injection molding machine original from Europe

Product attributes:

Condition: New

Place of Origin:Zhejiang, China (Mainland)

Oil tank capacity:400 L

Max Injection Volume: 850 ml

Heating Plate Dimension: 300×375 mm

System pressure:21 Mpa

Power: 90kw

Dimension (L×W×H): 3580×2020×(2750-3250)mm

Weight: 9.5 Ton

Certification: CE

Factory or not:Factory

Engineers:Portugal team

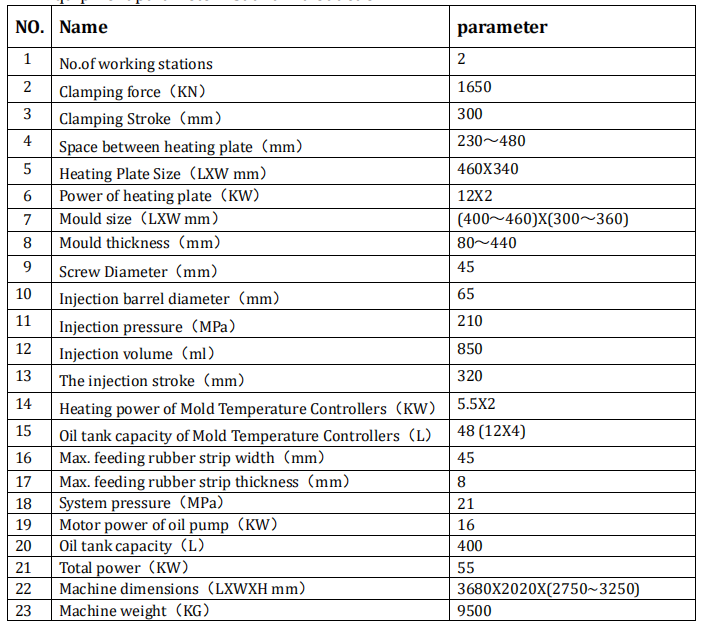

Single Color Rubber Sole Injection Molding Machine Technical Parameters:

1. European most advanced technology, specialized in the Rubber Shoe Sole Injection Molding technology. with Compact construction, Fully automated production.

2. Only need to put the rubber strip into the feeder, you can achieve automatic metering, preheating, injecting, and automatically moving out and opening mold. Full automated production process greatly improved production efficiency, reducing labor intensity, and protecting the mold.

3. Each Worker can easily operate 4-8 stations(2-4 machines), and each station can produce 20-35 Pairs of Shoe Soles per hour.

4. The process of injection after clamping, greatly reducing the product flash and trimming costs. The product is more compact, improve the intrinsic quality of the product.

5. With humanized interface, you can set the Curing Time, Injection Volume, Preheating Temperature, Curing temperature, Exhausting Parameters. And the Fault Diagnosis system can guide the maintenance staff to solve the problem in the shortest time.

6. Equipped with automatic Mold Change system. A mold can be replaced within five minutes.

7. Advanced energy-saving hydraulic control system can support 24 hours' continuous operation, with quickly response energy efficiency.

8. For Insert Color Process, single color injection machine will solve the rubber mixing problem easily, greatly improved the yield of the embedded color products, quality, and reduce costs of artificial re-treatment.

9. Optional Vacuum System, completely solve the problem of products with air.

10. Two kinds of heating systems are available, electrical heating and oil heating.

2. Only need to put the rubber strip into the feeder, you can achieve automatic metering, preheating, injecting, and automatically moving out and opening mold. Full automated production process greatly improved production efficiency, reducing labor intensity, and protecting the mold.

3. Each Worker can easily operate 4-8 stations(2-4 machines), and each station can produce 20-35 Pairs of Shoe Soles per hour.

4. The process of injection after clamping, greatly reducing the product flash and trimming costs. The product is more compact, improve the intrinsic quality of the product.

5. With humanized interface, you can set the Curing Time, Injection Volume, Preheating Temperature, Curing temperature, Exhausting Parameters. And the Fault Diagnosis system can guide the maintenance staff to solve the problem in the shortest time.

6. Equipped with automatic Mold Change system. A mold can be replaced within five minutes.

7. Advanced energy-saving hydraulic control system can support 24 hours' continuous operation, with quickly response energy efficiency.

8. For Insert Color Process, single color injection machine will solve the rubber mixing problem easily, greatly improved the yield of the embedded color products, quality, and reduce costs of artificial re-treatment.

9. Optional Vacuum System, completely solve the problem of products with air.

10. Two kinds of heating systems are available, electrical heating and oil heating.

FAQ

Please send your message to us

- Tel

- *Title

- *Content

subscription

Contact Person

- Name:

- Kayla He

- Tel:

86-18758629417

86-574-88033926

- Email:

- kayla@larytec.com

- Address:

- #1803, Huaxinjunting 1st Building, No.398 of Xiaying North Road, Panhuo Street,Yinzhou District, Ningbo, China

qr-code